John Mata Jr.

.

June 10, 2025

.

Tread

John Mata Jr.

.

June 10, 2025

.

Tread

The truck you are currently feasting your eyes on is a treat on so many levels. When Kevin Callaway decided to go all-in on his 1993 Dodge D250 build, he had a very tall list of features he wanted to include on the project. He also had a very restrictive budget, so Kevin knew from the jump that he was going to have to get creative, and basically handle all the design and labor duties to keep his costs down. The combination of Kevin having a mechanical engineering background, as well as having a lifelong interest in dirt bikes, ATVs, and RZRs, only solidified that the outcome of his project would result in a well-designed, war-ready rig.

From the start, Kevin was dead set on blasting his Dodge apart so he could fabricate a truck that was truly a representation of his imagination and passion for off-road automotive design. The first factory component to go was the entire chassis system. While there was nothing wrong with the frame, it honestly had zero chance of surviving the abuse Kevin was planning to inflict on his truck. In its place, Kevin began fabrication work on his own 2×6 3/16-inch tube chassis from the front to the back of the cab. Beyond that point, he made the rest of the frame from 3/16-inch brake metal. Kevin also put together his own laser-cut, CNC bent/rolled 2-inch DOM cage. Yeah, things got pretty wild in his garage!

This was a huge undertaking for sure, but he did his homework and had the design all figured out before he even bought any materials. Utilizing CAD software, Kevin cooked up and tweaked the entire chassis system to his specs to sidestep any potential pitfalls that go along with jumping in head-first and relying on trial and error. “The assembly process after CNC laser cutting and bending was effectively like a big LEGO set”, he admits. “Modeling everything in the computer saved me the need to rework anything on-the-fly. Not having to work around the factory frame and its mounting points really streamlined the process too.”

With the chassis fabrication coming along nicely, Kevin could then move onto putting suspension components into place. He chose Eibach springs for all four corners, and selected ICON 2.5 coilovers with 3.0 bypasses that were custom tuned by Downsouth Motorsports. Kevin ran with LSK Suspension trailing arms and a 4-link setup for the rear, constant caster with dual radius arms, and for protection of the undercarriage, he fabbed his own front and rear skid plates. The list of one-off features on this rig is truly head-spinning. The suspension system has 22 inches of travel up front, and the rear is strapped at 36—more than enough room for the 17-inch Walker Evans bead lock wheels and 40-inch BFG KR3 rubber!

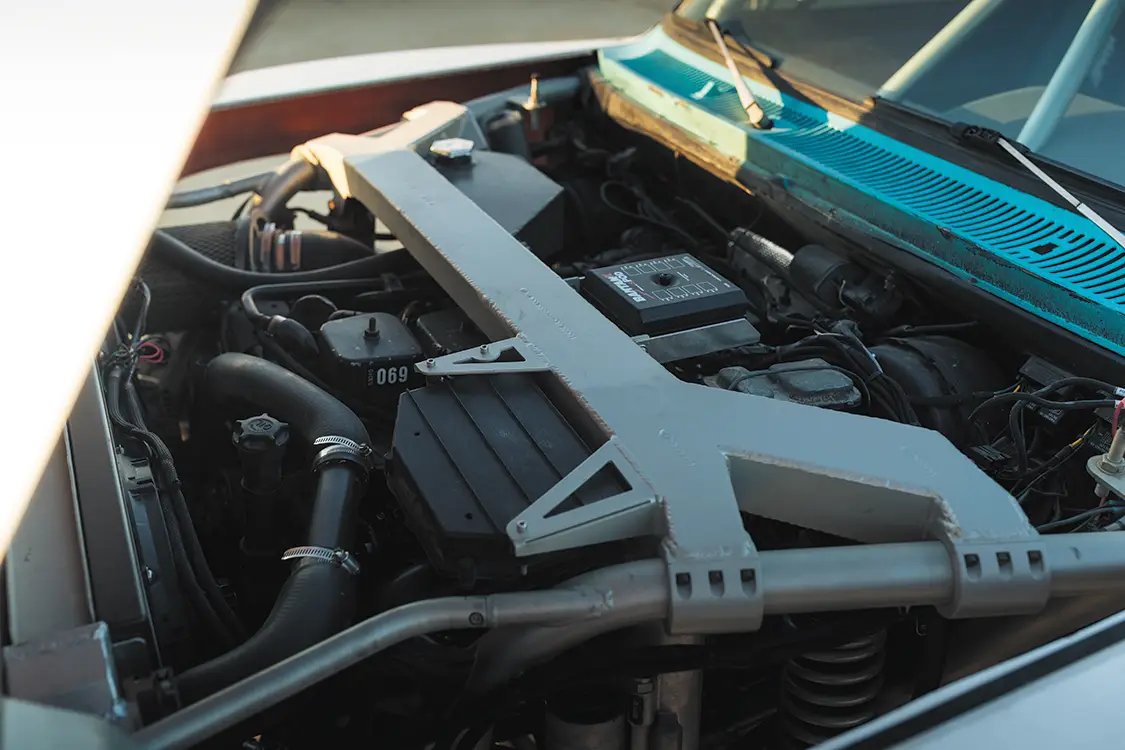

Even though Kevin was very much in the mindset to scrap most major factory Dodge components, he did stick with his D250’s stock 5.9L Cummins I-6 diesel engine. He designed custom mounts for it and transplanted a Duramax radiator and a 7.3L Powerstroke intercooler. Kevin created his own stainless pipe for the turbo, as well as 4-inch TIG-welded exhaust pipes that exit upward from the center of the bed. This configuration blows black smoke upward as he mashes on the gas pedal, which is a cool sight to see while he’s ripping through the sand. To further add a custom touch to the engine bay, Kevin designed his own hinges to swing the hood forward and over the grille, and an engine crossmember to allow for straightforward maintenance when the time comes. The level of execution here is just unreal.

A 48RE transmission was swapped in using a 2nd gen engine plate and full manual valve body. The Precision Performance Product ratchet-style shifter Kevin uses to move through the gears makes driving his Dodge a truly unique experience. It makes for race-inspired control instead of a typical gate shift sequence. Add that to the MPI steering wheel that Kevin has stuffed with even more functions and buttons on to keep him in control while staying focused on the terrain ahead. Other amenities in the cab include factory A/C and heat, an sPOD touch screen controller in the glovebox and billet switch on the dash, and an iPad mount for GPS function. Kevin designed his own intricate cage, which gets more impressive the closer you look at it.

Kevin plans to paint the truck in the future, but for now it’s looking good rocking Walker Evans-style fiberglass fenders from Trailer Products, a custom aluminum rear wing, and a TON of Baja Designs lights to ensure plenty of illumination during twilight rips through the dunes.

You’ll be hard pressed to find another truck like this one. It’s a lot to take in, and a bit difficult to wholly characterize in words within the structure of a feature story like this. Kevin set out to tailor a truck to his own standards, and it appears that he has achieved immense success. In just under 16 months, he created a truck that he essentially built from scratch. He drives this truck hard and takes great pride in the progress he has made so far. While it is a spectacular machine as it sits, there’s plenty more he’d like to improve upon in the future.

“For those looking to build a truck on your own, I would suggest staying true to what YOU want”, Kevin says. “When people say a certain truck can’t be good at something—it can be–and lots of fun too. Enjoy the process. Sometimes going further with your project can be easier in the long run because you are not building off subpar factory limitations.”.

Owner:

Kevin Callaway

El Cajon, CA

Engine & Drivetrain: 1993 Dodge 5.9L Cummins, Duramax radiator, 7.3L Powerstroke intercooler, HE351 turbo, Custom stainless turbo pipe, 4200 RPM governor spring, ARP studs, Coolant bypass at rear of block, Dynomite Diesel Stage 3 fuel injectors, High-volume fuel pump, Ratman Performance VE pump delivery valves, Custom 4-inch full stainless TIG welded exhaust system, 2006 Dodge 48RE transmission swap with 2nd gen engine plate, Power Driven Diesel manual valve body, DPC 1300 torque converter, G-Plus dual 25-row trans cooler in bed, Lockup and OD switch on steering wheel, Precision Performance Products shifter, 2WD transfer case, 1410 conversion with 2-piece driveshaft and plunge in rear shaft

Chassis & Suspension: Full custom chassis system, 2×6 3/16-inch tube frame to back of cab, custom 3/16-inch brake metal beyond, 128-inch wheelbase, I-beam front, 4-link rear setups, Eibach front and rear springs, ICON 3.0 bypass and 2.5 coilovers front and back, Downsouth Motorsports shock tune, Full 2-inch DOM cage laser-cut and CNC-bent/rolled, Swingset steering, Red-Head 1993 RAM quick steer ported, Constant caster with dual radius arm, LSK Suspension rear trailing arms, ¼-inch aluminum front and 3/8-inch stainless rear skid plates, 1996 Chevy 3500 dually 14-bolt rear, APEX truss on rear axle, 50-gallon fuel tank

Wheels, Tires & Brakes: 17×8.5 Walker Evans bead lock wheels, 40-inch BFG KR3 tires, 2010 Chevy 2500HD brakes, 2020 Duramax master cylinder, Tesla Bosch electric booster

Body & Paint: Aftermarket stock replacement grille, Truck-Lite headlights, Custom bumpers, Partial firewall cut/patch, Baja Designs (2) XL80 pod lights and (4) XL Racer pods on front bumper, (4) Squadron Pro amber lights on grille controlled with sPOD BantamX controller, RTL 30-inch chase light bar, RTL-M 6-inch lights on rear bumper, 0.063-inch-thick aluminum rear wing, Trailer Products Walker Evans-style fiberglass fenders

Interior: PRP Comp Elite seats, Black vinyl headliner, DOM 2-inch roll cage, GlowShift gauges, MPI drag racing steering wheel, Alpine stereo, Baja Designs dome lights, iPad mount for GPS, Race Radio, sPOD touch screen controller in glovebox, billet switch on dash

Share Link