DW STAFF

.

July 15, 2025

.

Diesel World

DW STAFF

.

July 15, 2025

.

Diesel World

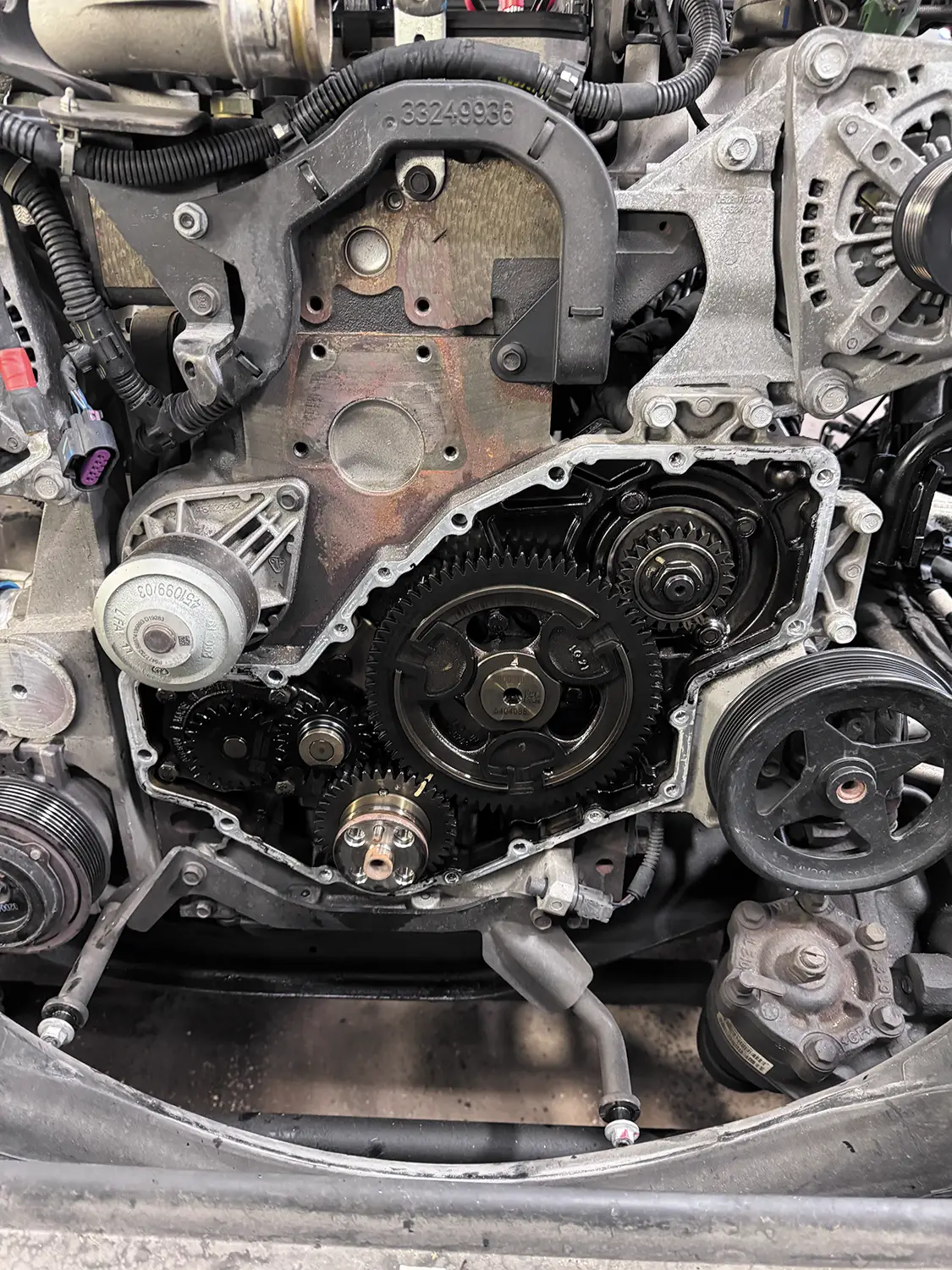

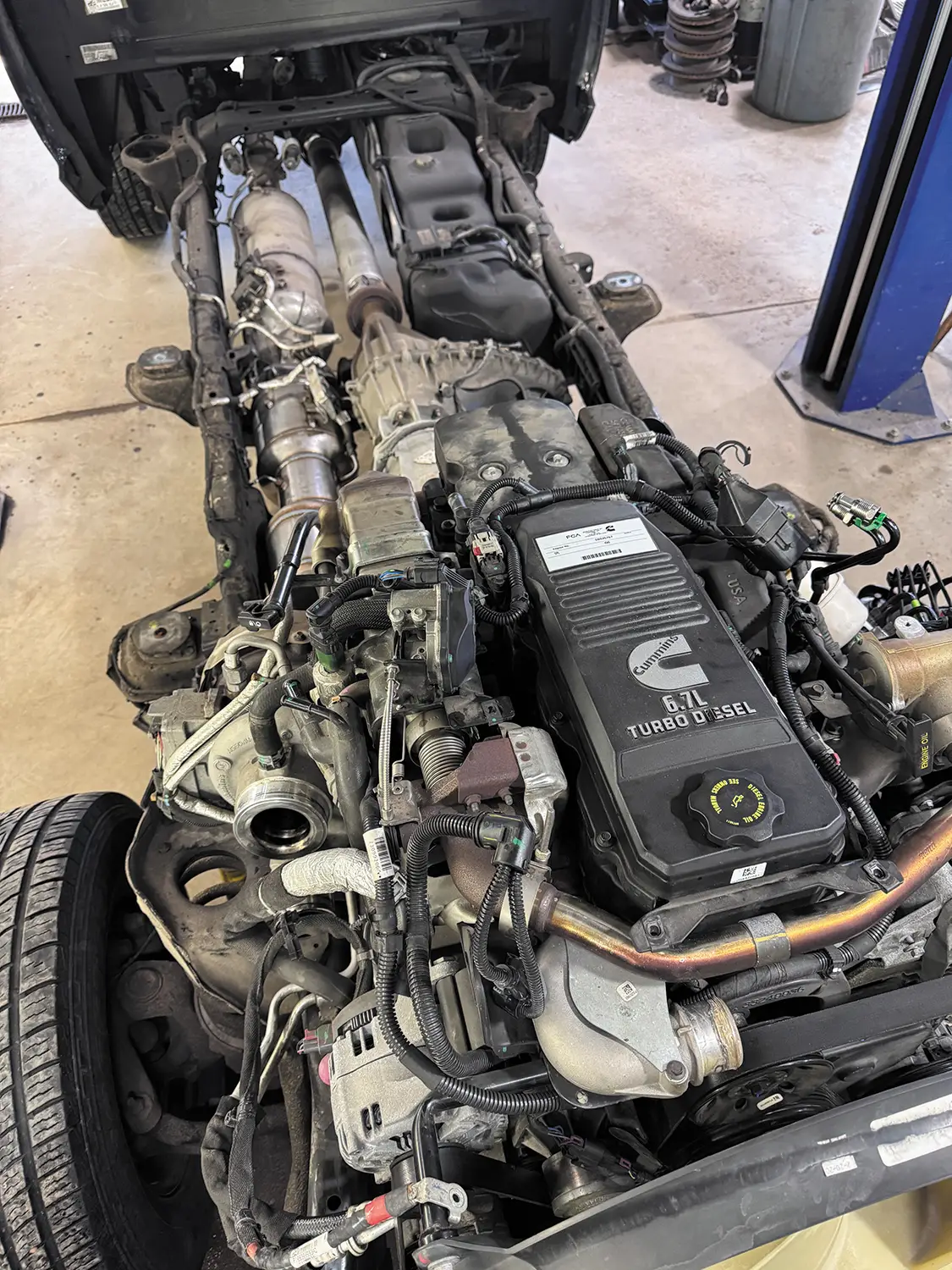

Emissions derates are an all-too-common occurrence on modern diesel trucks, but when a 67,000-mile 2020 Ram 2500 is throwing not only DPF performance and soot accumulation codes – but ash accumulation as well, it will raise some questions. With low miles and idle time, this system should have plenty of life left in it. Through testing, it was confirmed that the DPF was in fact plugged. Typically, there is an upstream issue that is the root cause of these problems, but with air, fuel, and turbocharger systems looking to be performing as they should and no supplemental codes, it made for a head-scratcher.

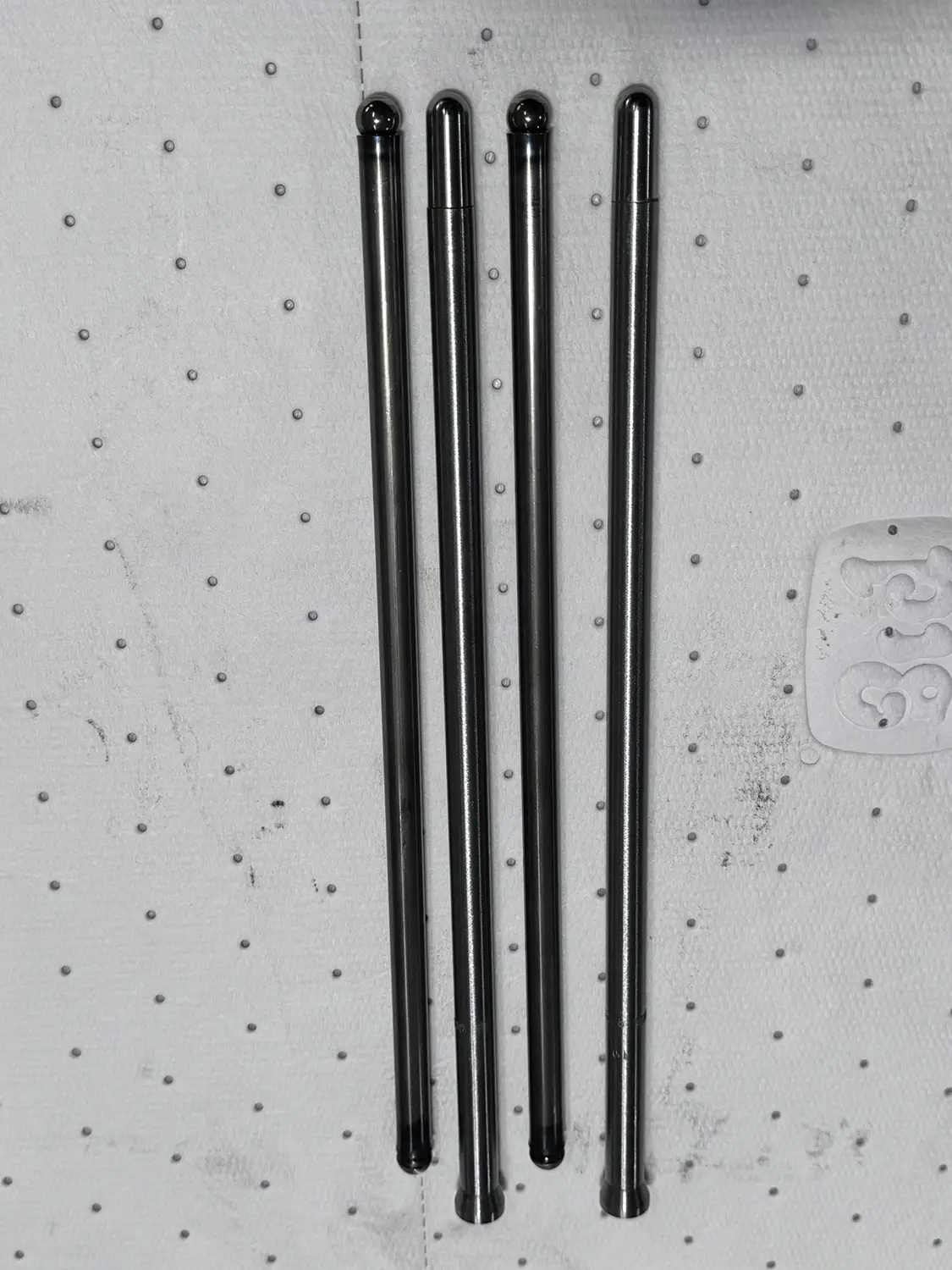

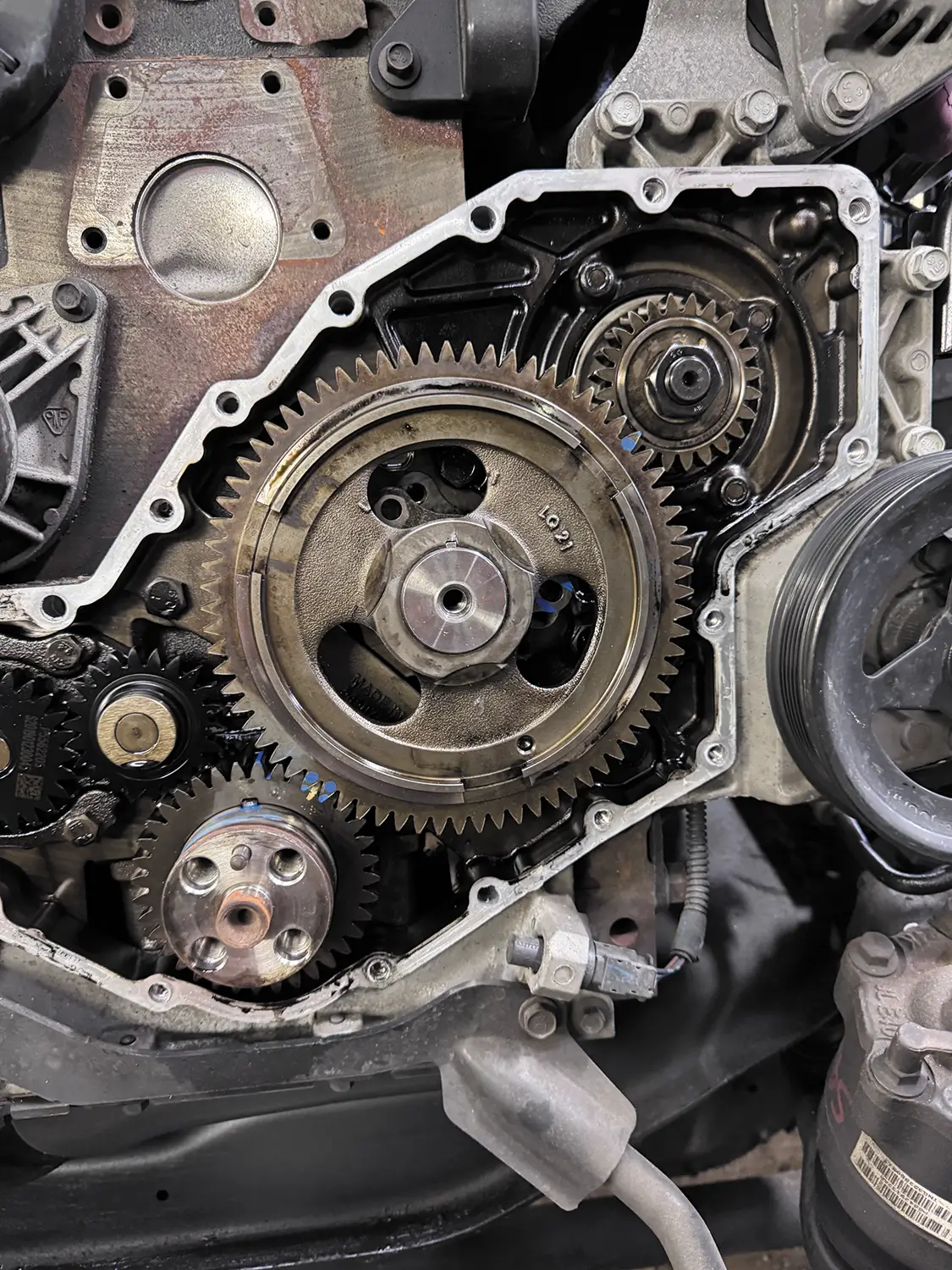

If you’re a 5th gen RAM owner, chances are that you’ve heard of (and lost sleep over) the issues with their hydraulic lifters. It may sound like a long shot on this one, but investigating the valvetrain on this truck proved to pay off. The exhaust pushrods on cylinders #2 and #5 had been taking a beating for some time and wearing down, which caused excessive valve lash and ultimately wreaked havoc downstream on the emissions system.

This is just one case of many in the world of 5th gen Cummins lifter failures. When it comes to the failures, there are two main failure modes:

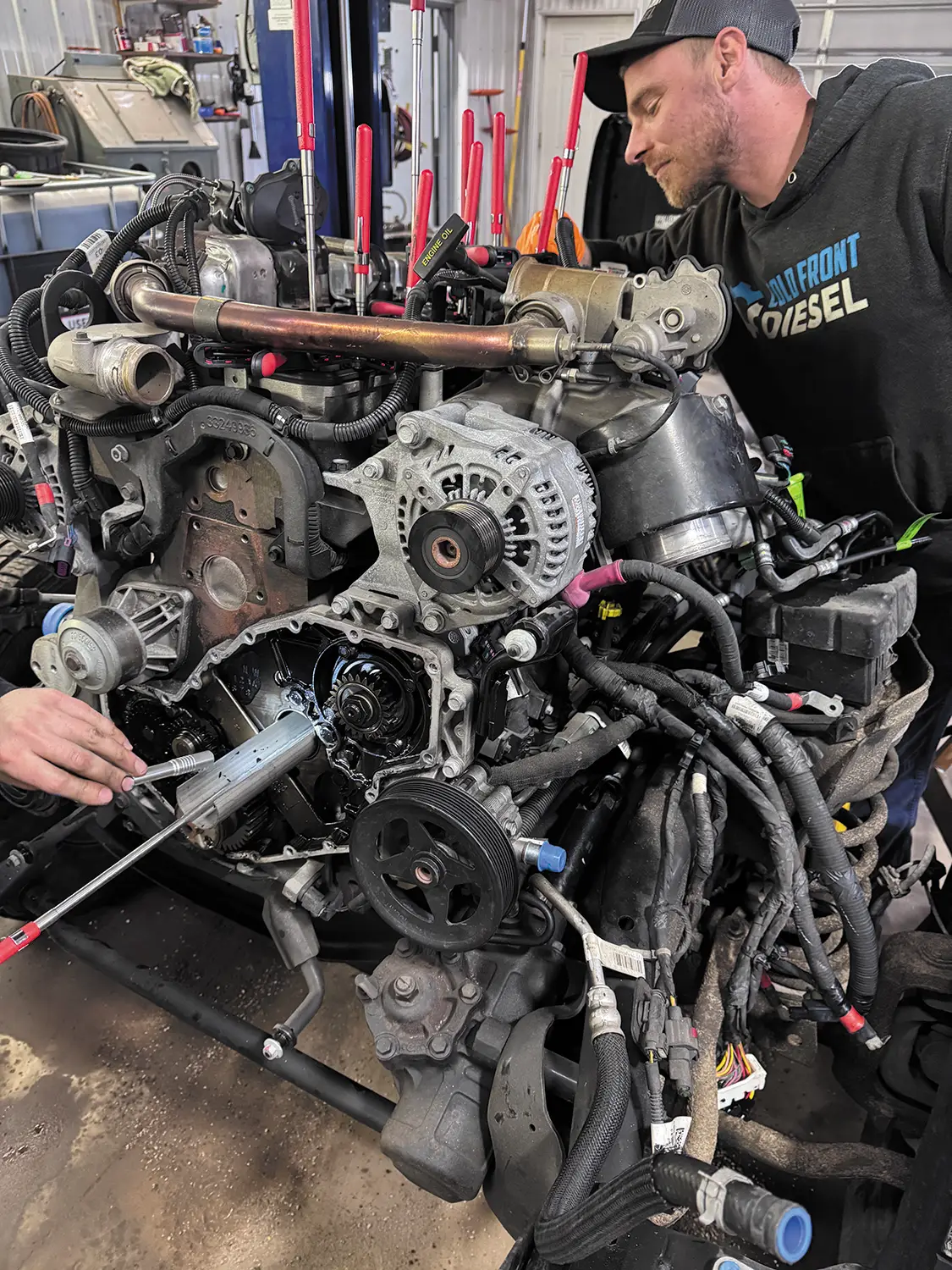

Fortunately, this issue can be resolved with the use of the Hamilton Flat Tappet Conversion Kit. This kit allows you to convert your 5th gen back to manual adjustable rockers and flat tappet lifters, similar to what is used in the previous generations of Cummins engines. Although they are similar in style, the Hamilton kit leaves no stone unturned in its design improvements.

Forged Steel Camshafts

DLC-Coated Tappets

Heavy-Duty Pushrods

Upgraded Rocker Arms

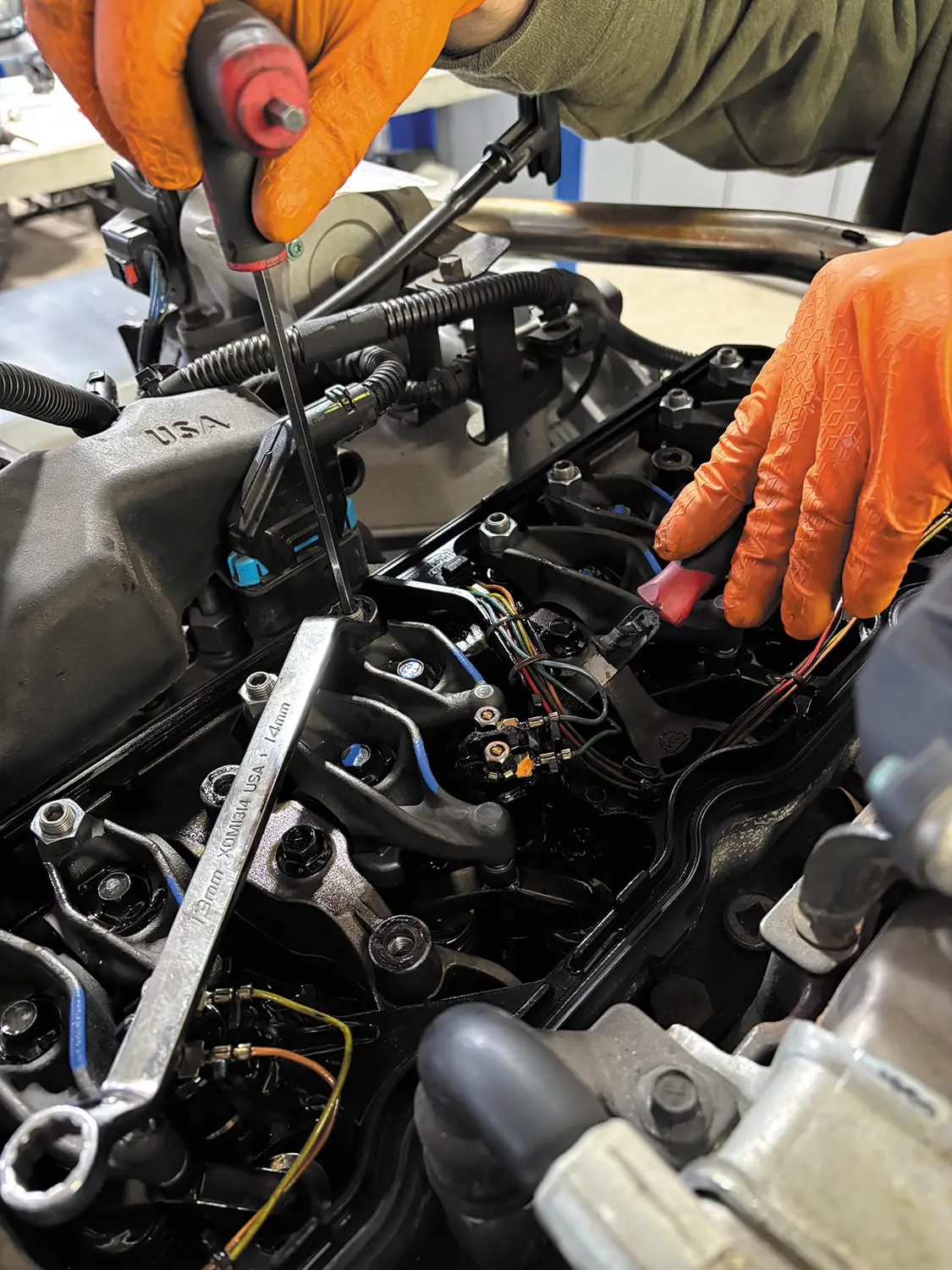

The installation process of this kit does require some expertise and specialty tooling to accomplish, but the kit itself is very complete and pretty straightforward for such a large-scale repair. The DLC coatings that are used provide for an easy break-in process due to their smooth, hard finish, but precautions should still be made to ensure an issue-free break-in process.

Some important steps to note during this install are:

Outside of a huge increase in reliability of your engine, you may notice improved spool-up, a slight increase in MPG, and a little more of that traditional diesel engine sound after installation. Whether you are making repairs caused by one of these failures or going to it for peace of mind, this is a setup that you won’t regret.

Share Link